Customized Nano Materials For Industrial Applications

A 5iTech Company

Advanced Performance Materials

TiO2 Nanostructured Thermal Spray Powder

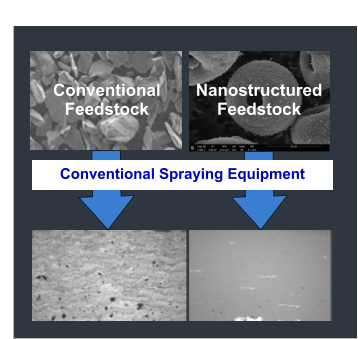

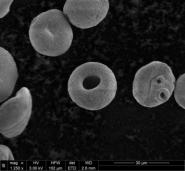

AlSher APM’s nanostructured powders produce superior coatings. These  powders can be sprayed using conventional equipment because nano particles

powders can be sprayed using conventional equipment because nano particles (<100nm) are combined into agglomerates that have the same particle size

(<100nm) are combined into agglomerates that have the same particle size distribution as regular micron sized feedstock. (Conventional thermal spray

distribution as regular micron sized feedstock. (Conventional thermal spray ceramic coatings are usually made from a powder feedstock with typical particle size

ceramic coatings are usually made from a powder feedstock with typical particle size distribution 5 to 100 microns.)

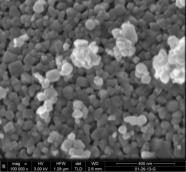

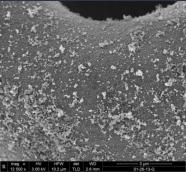

Coatings produced from our nanostructured agglomerates have a bimodal microstructure

distribution 5 to 100 microns.)

Coatings produced from our nanostructured agglomerates have a bimodal microstructure formed by semi-molten and fully molten particles. Due to this microstructure thermal

formed by semi-molten and fully molten particles. Due to this microstructure thermal spray coatings produced from nanostructured powders demonstrate superior durability

spray coatings produced from nanostructured powders demonstrate superior durability compared to conventional thermal spray coatings*.

compared to conventional thermal spray coatings*. AlSher APM proprietary production processes permit the manufacture of

AlSher APM proprietary production processes permit the manufacture of nanostructured thermal spray powders in ton quantities.

nanostructured thermal spray powders in ton quantities.

powders can be sprayed using conventional equipment because nano particles

powders can be sprayed using conventional equipment because nano particles (<100nm) are combined into agglomerates that have the same particle size

(<100nm) are combined into agglomerates that have the same particle size distribution as regular micron sized feedstock. (Conventional thermal spray

distribution as regular micron sized feedstock. (Conventional thermal spray ceramic coatings are usually made from a powder feedstock with typical particle size

ceramic coatings are usually made from a powder feedstock with typical particle size distribution 5 to 100 microns.)

Coatings produced from our nanostructured agglomerates have a bimodal microstructure

distribution 5 to 100 microns.)

Coatings produced from our nanostructured agglomerates have a bimodal microstructure formed by semi-molten and fully molten particles. Due to this microstructure thermal

formed by semi-molten and fully molten particles. Due to this microstructure thermal spray coatings produced from nanostructured powders demonstrate superior durability

spray coatings produced from nanostructured powders demonstrate superior durability compared to conventional thermal spray coatings*.

compared to conventional thermal spray coatings*. AlSher APM proprietary production processes permit the manufacture of

AlSher APM proprietary production processes permit the manufacture of nanostructured thermal spray powders in ton quantities.

nanostructured thermal spray powders in ton quantities.

Thermal spray coatings produced from nanostructured ceramic agglomerated powders can be tailored to different applications. Some of these applications demand coating properties with almost opposite

different applications. Some of these applications demand coating properties with almost opposite performance characteristics; for example, anti-wear and thermal barrier abradable coatings (TBC)*.

performance characteristics; for example, anti-wear and thermal barrier abradable coatings (TBC)*.  Nanostrustured Thermal Spray Coatings demonstrate superior durability and can significantly

Nanostrustured Thermal Spray Coatings demonstrate superior durability and can significantly improve performance and decrease service downtime for equipment. Therefore they are

improve performance and decrease service downtime for equipment. Therefore they are highly desirable in extreme conditions:

highly desirable in extreme conditions: •

Highly corrosive and abrasive environments in mining, ore purification, oil and gas drilling;

•

Salt water exposure of engines and components in ships, submarines, and underwater construction;

•

High temperature exposure and abrasion in gas turbine engines....

Our powders can be applied with consistency using Atmospheric Plasma Spray (APS), High Velocity Oxy

Fuel (HVOF) and Cold Spray Methods*.

We customize:

•

Particles Size distribution

•

Chemical Composition

•

Crystal Phase Composition

•

Highly corrosive and abrasive environments in mining, ore purification, oil and gas drilling;

•

Salt water exposure of engines and components in ships, submarines, and underwater construction;

•

High temperature exposure and abrasion in gas turbine engines....

Our powders can be applied with consistency using Atmospheric Plasma Spray (APS), High Velocity Oxy

Fuel (HVOF) and Cold Spray Methods*.

We customize:

•

Particles Size distribution

•

Chemical Composition

•

Crystal Phase Composition

different applications. Some of these applications demand coating properties with almost opposite

different applications. Some of these applications demand coating properties with almost opposite performance characteristics; for example, anti-wear and thermal barrier abradable coatings (TBC)*.

performance characteristics; for example, anti-wear and thermal barrier abradable coatings (TBC)*.  Nanostrustured Thermal Spray Coatings demonstrate superior durability and can significantly

Nanostrustured Thermal Spray Coatings demonstrate superior durability and can significantly improve performance and decrease service downtime for equipment. Therefore they are

improve performance and decrease service downtime for equipment. Therefore they are highly desirable in extreme conditions:

highly desirable in extreme conditions: •

Highly corrosive and abrasive environments in mining, ore purification, oil and gas drilling;

•

Salt water exposure of engines and components in ships, submarines, and underwater construction;

•

High temperature exposure and abrasion in gas turbine engines....

Our powders can be applied with consistency using Atmospheric Plasma Spray (APS), High Velocity Oxy

Fuel (HVOF) and Cold Spray Methods*.

We customize:

•

Particles Size distribution

•

Chemical Composition

•

Crystal Phase Composition

•

Highly corrosive and abrasive environments in mining, ore purification, oil and gas drilling;

•

Salt water exposure of engines and components in ships, submarines, and underwater construction;

•

High temperature exposure and abrasion in gas turbine engines....

Our powders can be applied with consistency using Atmospheric Plasma Spray (APS), High Velocity Oxy

Fuel (HVOF) and Cold Spray Methods*.

We customize:

•

Particles Size distribution

•

Chemical Composition

•

Crystal Phase Composition

For more information about Thermal Spray Powders and quotation requests please contact: info@alsherapm.com